Overview

Mpacts is simulation software which uses the Discrete Element Method (DEM) to understand, predict and solve industrial problems. It is estimated that around 80% of all industrial processes deal with particulate materials. Some examples are conveyor belts, hoppers, mixers, cyclones and tabletting machines. These phenomena are very hard to predict using classical Computational Fluid Dynamics (CFD) simulations. Mpacts has the potential to help design industrial processes with complex system properties.

Arbitrary shapes

For accurate simulations, accurate shape representations are crucial. Mpacts can represent any particle shape, eliminating the need to approximate the shape of the objects. This preserves the physical properties of the object, most notably the surface roughness.

The following shapes are included in rigid and deformable form in Mpacts: Spheres, cylinders, polyhedra, capsules, fibers, sheets and vesicles.

Damage modelling

Understanding how a product gets damaged or why it breaks apart is often of interest for robust and high quality production. The damage/breakage models included in Mpacts help to predict the onset and extend of damage and allow to continue the simulation with the damaged particles or particle fragments.

Because mechanisms vary greatly between products, custom damage/break model are supported.

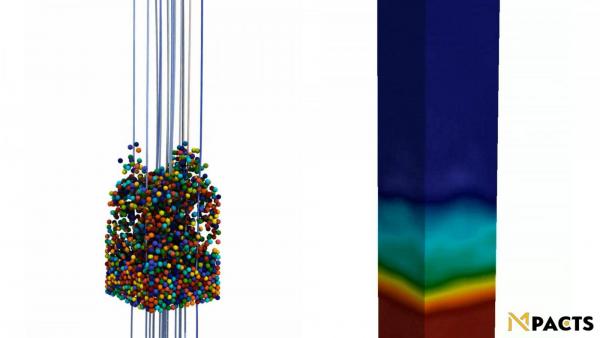

CFD coupling

Fluid flows are a crucial driving part of many processes. An example are fluidized beds. In this simulation, the particle movement and collisions are performed using the Discrete Element Method (DEM), while the fluid is simulated using Computational Fluid Dynamics (CFD). This is a two-way coupling: the particles influence the flow pattern, the flow will look for the 'easiest' path through the particle stacking, and the flow moves the particles through drag forces.

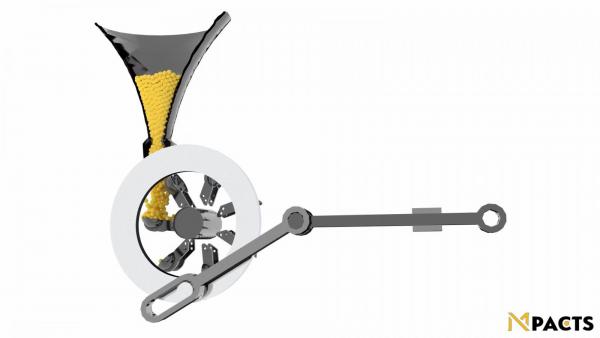

Rigid-body coupling

Parts of a machine are often mechanically linked, coupling their motions. The coupling is done through rotational or translational constraints or a combination of both.

The rigid-body functionality of Mpacts makes it easy to define a machine and ensures high speed simulations, even with a lot of linked parts.

Variability

When translating reality into a model it's to crucial to take variability into account. Sources of variablility can be: machine tolorances, particle shapes and material properties such as stiffness and damping. Especially when working with biological material, the variability can be large.

Variability can be included in a single simulation, e.g. sample particle stiffness from measured results. In this way, the particle population should be representative for the measured population. However, differences between measured populations can exist as wel, e.g.: date of measurement, supplier. To take this into account, Mpacts has tools to automatically generate a set of simulations and report the effect on output quantities of interest to the user.

User modules

Because every challenge is different, Mpacts supports custom user models. These models can be written in either Python, or if preformance is critical in c++.

This is done through a powerful Python/C++ API. Documentation and tuturials are available to access the power of DEM simulations at your fingertips.